Category: Flat Fenders

Tags: Body & Frame, Exterior Parts & Car Care, Fender Flares, Fenders

Brand: Smittybilt

Flat Fenders

XRC Fender Flares 07-18 Wrangler JK Set Of 4 Black Textured 2DR/4DR Smittybilt – 76837

XRC Fender Flares feature 100 percent steel construction for extra durability. Each XRC Fender Flare is powder coated for immediate use and durability, or they can be painted to color match your ride. XRC Fenders are streamline designed to help increase suspension articulation while maintaining the street-ability look.

Details:

- Fits 2007 to 2018 Wrangler, Rubicon and Unlimited

- 2 and 4-door models

- Powder coated black for immediate use or can be painted

- 4-piece set

- 100 percent steel construction for extra durability

$299.99

Related products

-

Flat Fenders

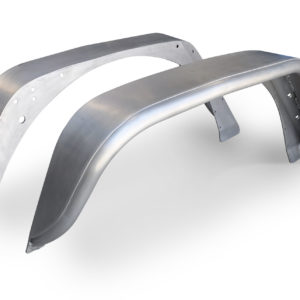

JK Rear Crusher Flares Extra Wide (Aluminum) Poison Spyder – 17-05-020-ALUM

0 out of 5(0)JK Rear Crusher Flares Extra Wide (Aluminum) for Jeep Wrangler JK 2007-2016. These Extra Wide JK Crusher Flares are 2 inches wider than our Standard Width Crusher Flares. This gives you 2 inches of extra tire coverage to help comply with local tire coverage laws while keeping more dirt and mud from being flung up on to the side of the Jeep by wider wheels and tires. The Jeep JK thin sheet metal fenders and Stock plastic flares are among the most vulnerable body components when traversing the trail. Poison Spyder JK Crusher Flares improve both the aesthetics and durability of your Jeep during your off road adventures. Crusher Flares and Poison Spyders exclusive Inner Brace system are the ultimate in front fender armor for your JK, with the toughness to withstand punishing scrapes with granite canyon walls. This product ships as bare steel it will need to be painted or powdercoated prior to final installation.

Features:

- Replace flimsy plastic OE fender flares with rugged 6061-T6 Aluminum alloy

- 2 inches wider than our Standard Width Crusher Flares

- CNC laser cut 3/16 inch mounting plate and 1/8 inch top plate

- NC bent 1.5 inch OD X .188 wall DOM tube outer rub rail

- Internal bracing kit transfers impact loads to Jeep heavy gauge inner tub structure

- Bare Finish

- Sold As A Pair

The Poison Spyder JK Crusher Flare provides tire coverage for up to a 40 inch tire (minor trimming of the inner sheet metal may be required for tire clearance). The Crusher Flares mounting plate is made of CNC laser cut 3/16 inch plate steel that has been brake-formed to fit the contours of the JK flare mounting surface like a glove. The Crusher Flare rails are CNC-bent 1.5 inch X .188 wall DOM structural tubing, with a fender surface made of 1/8 inch laser-cut plate aluminum.

The Crusher Flare mounts using stainless steel countersunk flat head cap screws that provide a low profile, great looks and corrosion resistance. Installation requires drilling and installation of the provided nut-sert fasteners. Poison Spyder supplies a simple nut-sert installation tool to facilitate the process. Crusher Flares are sold as bare steel. For added structural rigidity when hardcore wheeling, Rear Crusher Flares come with a 4-piece Inner Brace Kit. The Inner Braces are engineered to provide the internal structure to keep the Crusher Flares from deforming the Jeep outer tub sheetmetal on impacts. The components are laser-cut and brake-formed to precisely fit between the Jeep outer sheet metal and the heavier gauge steel of the structural inner tub. The result is a Crusher Flare installation that will withstand serious hits from the rocks.

Extra-Wide

Extra-Wide Crusher Flares are designed for those Jeepers who need extra tire coverage to satisfy local laws, or who simply want to keep more dirt and mud from flinging up onto the Jeep due to wide wheels and tires. These Extra-Wide Crusher Flares measure 10.75 inches wide at the widest point (measured from the Jeep body sheet metal). Compared to the Stock plastic flares and our Standard Width Crusher Flares which both measure 8.75 inches, the Extra-Wide Crusher Flares provide an extra 2 inches of tire coverage. Not only are they wider at the top, they also stay wider toward the bottom for better mud-guard functionality. Poison Spyder also offers matching Extra-Wide Rear Crusher Flares.

Roll-Bent Outer Tubes

Poison Spyder Crusher Flares were the first all-metal armored flare on the market when the Jeep JK debuted with the 2007 model year. Since then dozens of companies have tried to duplicate the original. But Poison Spyder stays a step ahead, and Now Crusher Flares are the only metal armored flare on the market constructed with CNC Roll-Bent Outer Tubes. Using the latest technology in computer-controlled roll-benders to form these tubes results in several advantages. First, and Most obviously, roll-bending results in a much more elegant product, whose subtle curves match the lines of the Jeep JK perfectly. Our competitors products are easy to spot because parts made on traditional tube benders have sharp, segmented bends that simply cant match the Jeep body lines as well. The other benefit is that roll-bending is a gentler process, resulting in less weakening of the tube where it stretches or compresses around bends. Only Poison Spyder Crusher Flares are manufactured with this state-of-the-art CNC roll-bending process!

Construction

Steel JK Crusher Flares are constructed using 1.5 inch X .188 wall DOM (Drawn-Over-Mandrel) structural tubing as the outer rub rail. This DOM tubing provides better resistance to crushing, kinking, and bending than competitors flares made with thinner wall, welded seam tubing. The foundation of the Crusher Flare is a CNC laser cut, 3/16 inch thick aluminum mounting plate, precision brake-formed to conform to the subtle curves of the JK body panels. Mounting holes are countersunk for the use of flat-head stainless steel mounting hardware. The top plate is CNC laser cut 1/8 inch aluminum plate, which is hand formed around the curves of the Crusher Flare for a factory appearance that matches the JK organic body lines better than any other aftermarket metal flare available.

Exclusive Inner Brace Set

Every set of Poison Spyder JK Crusher Flares comes with a set of inner braces that tie the Crusher Flare in to the sturdier, heavier-gauge steel of the JK inner body tub structure. Competitors JK Flare products simply bolt directly to the outer layer of the JK body sheetmetal. But as any JK owner kNows, the exterior sheet metal is very thin and flexible. Simply bolting a heavy duty fender directly to the exterior sheet metal without the inner bracing is a disaster waiting to happen. Regardless of how sturdy the flare is built, upon contact with rocks, trees, etc. it will simply push in and deform the flimsy sheet metal it is bolted to, possibly causing expensive and unsightly damage.The Inner Brace Set that comes with Poison Spyder Crusher Flares effectively bypasses the outer sheetmetal, instead transferring those forces to the much stronger inner structure of the Jeep. These Inner Braces are CNC laser cut, brake-formed for a great fit and simple installation.

Provisions for LED Marker Lamps

JK Front Crusher Flares come Standard with mounting provisions to replace the factory side marker with a high intensity 3/4 inch round LED marker light (sold separately in red, amber or clear/amber). The addition of the LED provides a more modern and refined look that complements the function and style of the Crusher Flare.

Steel or Aluminum?

Not sure whether to choose steel or aluminum for your Crusher Flares? Aluminum is lighter in weight, so might be the best choice for those looking to save weight on their heavy JKs in order to improve fuel mileage and gain an advantage off-road. However, when wheeling with aluminum flares it is up to the driver to use more care and finesse, as the aluminum components are Not going to be able to withstand the same direct impacts that steel can. The outer tube on our aluminum Crusher Flares is beefy .188 wall thickness. Compared to our steel Crusher Flares which use .120 wall DOM steel tubing. The thicker tube wall recoups some of the strength lost by going to aluminum, however the steel versions will still be stronger in a direct impact with the rocks. For reference, an aluminum product general weighs 1/3 to 1/2 the weight of its steel counterpart.SKU: 17-05-020-ALUM-PSC$648.99 -

Flat Fenders

Jeep JK 2/4 Door Notorious Dovetail Rear Fender Flare 07-18 Wrangler JK Unfinished Nemesis Industries

Flat Fenders

Flat FendersJeep JK 2/4 Door Notorious Dovetail Rear Fender Flare 07-18 Wrangler JK Unfinished Nemesis Industries

0 out of 5(0)When Nemesis set its sights on developing body armor for the JK Wrangler, we we knew we wanted to change the game. We wanted to build the highest quality, most attractive fender available for the JK platform. Like all of Nemesis products, they had to be lightweight, high clearance and strong, built using Nemesis superior aluminum manufacturing techniques.

The result was the Notorious Fender Flare, a high clearance flare with style and class unmatched and unrivaled by other armor manufacturers. The Notorious rear flare offers high clearance for big tires on mild lift kits and is perfect for a daily driven JK that still sees heavy trail use. It maintains factory rear tire coverage to keep your rig road legal while making the rear corner of your Jeep much more bash resistant. It is constructed of formed aluminum and reinforced in all of the proper locations to provide maximum protection while keeping the weight down.

Notorious flares have the Skeletos upgrade as an option. Without the Skeletos upgrade, the flare is designed to absorb the biggest impacts, keeping the factory sheet metal straight. With the Skeletos upgrade, the flare is able to withstand even more punishment, able to be used to pivot off of obstacles and take large hits, but may transfer the force to the sheet metal.

Build Specs

- Finish: Bare

- JK Notorious Rear Flare-No Skeletos

- 2007-Current JK 2/4 Door

- Sold As Pair

Nemesis superior construction

Built from high strength 3/16 inch aluminum

Factory tire coverage

Formed and welded using Nemesis proprietary manufacturing techniques using hand built custom tooling

Seamless finish

Inspected for precision fit and finish to Nemesis high standards, fits right the first timeNotes

Skeletos upgrade available

Available in raw, black or textured powder coatInstallation

Installation can be handled by the average home installer, and can be completed in three hours for the pair, using basic hand tools and a drill.

SKU: 126500-HCQS$649.00 -

Flat Fenders

UAS Maximus Flat Fenders Jeep JL

0 out of 5(0)Set of 4 Jeep JL flat fenders. The fender flare components are manufactured from the highest quality material obtainable for durability and impact resistance. Constructed out of reinforced fiberglass with a smooth gel coat finish and ready for paint.

- Pre-drilled holes for easy bolt on installation

- Durable 3/16″ fiberglass construction – hand laid with woven reinforcemen

- Ready for Paint

- Exceptional Strength, Durability and Impact Resistance

- Allows installation of larger diameter tires than stock fenders

- Attractive design

- Made with Pride in the USA

JL pictured has a 3.5″ lift with 40’s

SKU: UAS-JL$1,299.00$1,499.00 -

Flat Fenders

JK Rear Crusher Flares Standard Width (Steel) Black Poison Spyder – 17-05-010P1

0 out of 5(0)JK Rear Crusher Flares Standard Width (Steel) Black for Jeep Wrangler JK 2007-2016. The Jeep JK thin sheetmetal fenders and stock plastic flares are among the most vulnerable body components when traversing the trail. The Poison Spyder JK Rear Crusher Flare kit improves both the aesthetics and durability of your Jeep during your off road adventures. Poison Spyder Standard Width JK Crusher Flares provide tire coverage similar to the factory flares, with the added advantage of a better departure angle and outer tire clearance. Steel Crusher Flares and Poison Spyder exclusive Inner Brace system are the ultimate in fender armor for your JK, with the toughness to withstand punishing scrapes with granite canyon walls. This product is finished in black with Poison Spyder proprietary SpyderShell Armor Coat process.

Features:- Replace flimsy plastic OE fender flares with heavy duty steel

- Standard Width mimics approximate width of Stock fender flares

- CNC laser cut 3/16 inch mounting plate and 1/8 inch top plate

- NC bent 1.5 inch OD X .120 wall DOM tube outer rub rail

- Internal bracing kit transfers impact loads to Jeep heavy gauge inner tub structure

- Black Spydershell Armor Coat Finish

- Sold As A Pair

Roll-Bent Outer Tubes

Poison Spyder Crusher Flares were the first all-metal armored flare on the market when the Jeep JK debuted with the 2007 model year. Since then dozens of companies have tried to duplicate the original. But Poison Spyder stays a step ahead, and now Crusher Flares are the only metal armored flare on the market constructed with CNC Roll-Bent Outer Tubes. Using the latest technology in computer-controlled roll-benders to form these tubes results in several advantages. First, and most obviously, roll-bending results in a much more elegant product, whose subtle curves match the lines of the Jeep JK perfectly. Our competitors products are easy to spot because parts made on traditional tube benders have sharp, segmented bends that simply cant match the Jeeps body lines as well. The other benefit is that roll-bending is a gentler process, resulting in less weakening of the tube where it stretches or compresses around bends. Only Poison Spyder Crusher Flares are manufactured with this state-of-the-art CNC roll-bending process!

SpyderShell Armor Coat

SpyderShell is more than just powder coating—its a complete system that includes the state of the art in preparation, application, materials and packaging to ensure that your SpyderShell products stay looking great for years. The SpyderShell process has been engineered to provide your Poison Spyder product with years of unmatched great looks, corrosion protection and weather-resistance. Our proprietary 6-stage system starts with media blasting the entire part, to remove contaminents and prep the metal surface for the best possible adhesion. Next, any seams are sealed with 3M Scotch-Weld to block moisture from entering and causing corrosion where the powder can Not reach. The first coat to be applied is a zinc-rich powdered black primer, which is baked on to form an impenetrable bond between the metal product and the coating. The primer is black–rather than traditional gray–so that any rock chips or trail damage are less conspicuous. The final top coat is an industrial grade, super-durable architectural finish in semi-gloss black, which is engineered to retain its appearance through years of exposure to sun and weather. SpyderShell is a coating process unmatched by any other Jeep armor aftermarket manufacturer, for which we are confident in offering a 5-year warranty on materials and workmanship.

Exclusive Inner Brace Set

Every set of Poison Spyder JK Crusher Flares comes with a set of inner braces that tie the Crusher Flare in to the sturdier, heavier-gauge steel of the JK inner body tub structure. Competitors JK Flare products simply bolt directly to the outer layer of the JK body sheetmetal. But as any JK owner knows, the exterior sheetmetal is very thin and flexible. Simply bolting a heavy duty fender directly to the exterior sheetmetal without the inner bracing is a disaster waiting to happen. Regardless of how sturdy the flare is built, upon contact with rocks, trees, etc., it will simply push in and deform the flimsy sheetmetal it is bolted to, possibly causing expensive and unsightly damage. The Inner Brace Set that comes with Poison Spyder Crusher Flares effectively bypasses the outer sheetmetal, instead transferring those forces to the much stronger inner structure of the Jeep. These Inner Braces are CNC laser cut, brake-formed for a great fit and simple installation.

Provisions for LED Marker Lamps

The JK Rear Crusher Flare Kit comes standard with mounting provisions to place a small 3/4 inch LED marker lamp inside the flare just rearward of the tire. The LED can be wired in to the Jeeps running lights or turn signal circuits. 3/4 inch amber LED lamps are available separately from Poison Spyder.

Steel or Aluminum?

Not sure whether to choose steel or aluminum for your Crusher Flares? Aluminum is lighter in weight, so might be the best choice for those looking to save weight on their heavy JKs in order to improve fuel mileage and gain an advantage off-road. However, when wheeling with aluminum flares it is up to the driver to use more care and finesse, as the aluminum components are Not going to be able to withstand the same direct impacts that steel can. The outer tube on our aluminum Crusher Flares is beefy .188 wall thickness. Compared to our steel Crusher Flares which use .120 wall DOM steel tubing. The thicker tube wall recoups some of the strength lost by going to aluminum, however the steel versions will still be stronger in a direct impact with the rocks. Aluminum JK Crusher Flares are less than half the weight of the steel version. Which is best for you will depend on your particular intended use of the Jeep, driving style and other factors.SKU: 17-05-010P1-PSC$668.99 -

Flat Fenders

JK Front Crusher Flares Narrow Width (Steel) Poison Spyder – 17-03-031

0 out of 5(0)JK Front Crusher Flares Narrow Width (Steel) for Jeep Wrangler JK 2007-2016. These Narrow JK Crusher Flares are 2 inches narrower than our Standard Width Crusher Flares. This gives you 2 inches of extra clearance from canyon walls, trees and obstacles on tight trails. The Jeep JKs thin sheet metal fenders and Stock plastic flares are among the most vulnerable body components when traversing the trail. The Poison Spyder JK Front Crusher Flare kit improves both the aesthetics and durability of your Jeep during your off road adventures. Steel Crusher Flares and Poison Spyders exclusive Inner Brace system are the ultimate in front fender armor for your JK, with the toughness to withstand punishing scrapes with granite canyon walls. This product ships as bare steel it will need to be painted or powdercoated prior to final installation. We do Not offer a powdercoat option for this item.

Features:

- Replace flimsy plastic OE fender flares with heavy duty steel

- Narrow Width is 2 inches narrower than Standard Width flares (check your local tire coverage laws before ordering)

- CNC laser cut 3/16 inch mounting plate and 1/8 inch top plate

- CNC roll-bent 1.5 inch OD X .120 wall DOM tube outer rub rail

- Roll-bending gives smooth, sweeping, continuous bends that match the Jeep lines perfectly

- Internal bracing kit transfers impact loads to Jeep heavy gauge inner tub structure

- Bare Finish

- Sold As A Pair

Construction

Steel JK Crusher Flares are constructed using 1.5 inch X .120 wall DOM (Drawn-Over-Mandrel) structural tubing as the outer rub rail. This DOM tubing provides better resistance to crushing, kinking, and bending than competitors flares made with thinner wall, welded seam tubing. The foundation of the Crusher Flare is a CNC laser cut, 3/16 inch thick steel mounting plate, precision brake-formed to conform to the subtle curves of the JKs body panels. Mounting holes are countersunk for the use of flat-head stainless steel mounting hardware. The top plate is CNC laser cut 1/8 inch steel plate, which is hand formed around the curves of the Crusher Flare for a factory appearance that matches the JKs organic body lines better than any other aftermarket metal flare

Exclusive Inner Brace Set

Every set of Poison Spyder JK Crusher Flares comes with a set of inner braces that tie the Crusher Flare in to the sturdier, heavier-gauge steel of the JKs inner body tub structure. Competitors JK Flare products simply bolt directly to the outer layer of the JKs body sheet metal. But as any JK owner kNows, the exterior sheet metal is very thin and flexible. Simply bolting a heavy duty fender directly to the exterior sheet metal without the inner bracing is a disaster waiting to happen. Regardless of how sturdy the flare is built, upon contact with rocks, trees, etc., it will simply push in and deform the flimsy sheet metal it is bolted to, possibly causing expensive and unsightly damage.The Inner Brace Set that comes with Poison Spyder Crusher Flares effectively bypasses the outer sheet metal, instead transferring those forces to the much stronger inner structure of the Jeep. Thats why weve been able to demonstrate the strength of our flare attachment system by parking aNother Jeep on top of the Crusher Flare! These Inner Braces are CNC laser cut, brake-formed for a great fit and simple installation.

Rubber Liners Included

JK Front Crusher Flares come with high quality rubber liners to place between the Crusher Flare and the Jeep body sheet metal during installation. The rubber liners provide help protect your Jeep exterior paint, where the flare contacts it. It also helps even out the contact area of the Crusher Flare, absorbing any small bumps or imperfections between the mated surfaces. The rubber liner also helps keep moisture, dirt and debris from collecting between the Crusher Flare and the Jeep body. These liners are cut from premium EPDM rubber.

Retain Factory Wheel Wells

When installing Poison Spyder JK Front Crusher Flares you have the option of retaining the factory wheel well liner to protect the engine from trail and road debris. Retaining the wheel well also helps to conceal the Inner Braces to complete a clean and finished appearance. Some trimming of the plastic wheel well is required, but the kit comes with hardware and mounting brackets to re-install the trimmed wheel well.

Provisions for LED Marker Lamps

The JK Front Crusher Flare kit comes Standard with mounting provisions to replace the factory side marker with a high intensity 3/4 inch round LED marker light. The addition of the LED provides a more modern and refined look that complements the function and style of the Crusher Flare.

Steel or Aluminum?

Not sure whether to choose steel or aluminum for your Crusher Flares? Aluminum is lighter in weight, so might be the best choice for those looking to save weight on their heavy JKs in order to improve fuel mileage and gain an advantage off-road. However, when wheeling with aluminum flares it is up to the driver to use more care and finesse, as the aluminum components are Not going to be able to withstand the same direct impacts that steel can. The outer tube on our aluminum Crusher Flares is beefy .188 wall thickness. Compared to our steel Crusher Flares which use .120 wall DOM steel tubing. The thicker tube wall recoups some of the strength lost by going to aluminum, however the steel versions will still be stronger in a direct impact with the rocks. For reference, a steel JK Front Crusher Flare weighs 31.6 lbs (Not including hardware), while an aluminum one weighs only 11.8 lbs. Which is best for you will depend on your particular intended use of the Jeep, driving style and other factors.SKU: 17-03-031-PSC$508.99